I. Introduction

Fire safety and prevention are of utmost importance in order to protect lives, property, and the environment. Fires can occur unexpectedly and can cause tremendous damage if not properly managed. One crucial tool in fire safety is the fire extinguisher, which can help control and extinguish small fires before they escalate. Dry chemical fire extinguishers are commonly used for their effectiveness, versatility, and ability to suppress flames rapidly. In this article, we will explore the understanding, benefits, and applications of dry chemical fire extinguishers.

II. Understanding Dry Chemical Fire Extinguishers

A. What is a dry chemical fire extinguisher?

A dry chemical fire extinguisher is a portable device specifically designed to extinguish fires by delivering dry chemical agents onto the flames. The dry chemical agents used in these extinguishers are fine powders that work by interrupting the chemical reaction of the fire, thus suppressing the flames. The composition of the dry chemical agents may vary, but they commonly contain substances such as monoammonium phosphate, sodium bicarbonate, or potassium bicarbonate.

Different types of dry chemical agents are suitable for specific classes of fires. It is essential to understand the types of fires suitable for dry chemical extinguishers to ensure their effective use.

B. How do dry chemical fire extinguishers work?

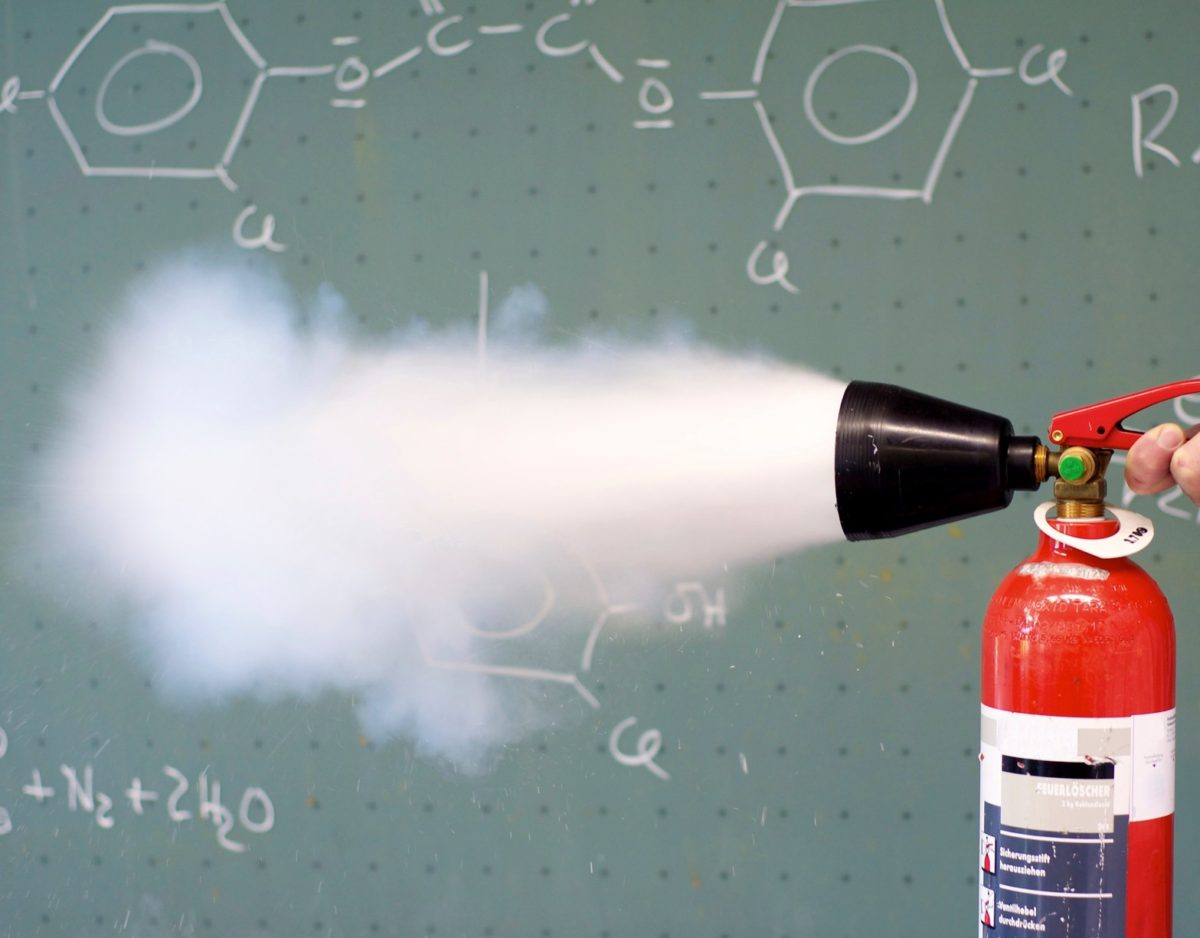

Dry chemical fire extinguishers work by interrupting the fire’s chemical reaction. When the extinguisher is discharged, the dry chemical agent is expelled onto the flames in the form of a fine powder. The powder acts as a barrier, separating the fuel from the oxygen in the air, thereby preventing the fire from re-igniting.

There are two main application methods when using dry chemical fire extinguishers: the direct discharge method and the sweeping method. In the direct discharge method, the extinguisher is aimed at the base of the flames, targeting the fuel source directly. This method is effective for smaller fires. The sweeping method involves sweeping the extinguisher from side to side across the flames to cover a wider area. This method is suitable for larger fires that require a broader application of the extinguishing agent.

III. Benefits and Applications of Dry Chemical Fire Extinguishers

A. Versatile use across various fire classes

One of the significant advantages of dry chemical fire extinguishers is their versatility in suppressing different classes of fires. The classes of fires are categorized as follows:

- Class A fires: Combustible materials such as wood, paper, textiles, and plastics. Dry chemical extinguishers are highly effective in smothering these fires by creating a barrier between the fuel and oxygen.

- Class B fires: Flammable liquids and gases such as gasoline, oil, propane, and natural gas. Dry chemical extinguishers can rapidly suppress these fires by interrupting the chemical chain reaction.

- Class C fires: Fires involving energized electrical equipment. Dry chemical extinguishers are non-conductive and can be used on live electrical equipment without the risk of electric shock.

- Class D fires: Fires involving combustible metals such as magnesium, titanium, or sodium. Dry chemical agents specifically designed for class D fires can suppress and cool these fires, preventing further oxidation.

B. Effectiveness in suppressing flames

Dry chemical fire extinguishers demonstrate rapid flame knockdown properties, meaning they can quickly suppress flames upon discharge. The fine powder form of the dry chemical agent allows for efficient coverage of the fire, smothering the flames effectively. This rapid flame knockdown property is crucial in preventing the fire from spreading and causing more extensive damage.

Furthermore, dry chemical agents have the ability to create a barrier between the fuel and oxygen, preventing re-ignition. Even after the flames have been extinguished, the powder residue left by the dry chemical agent continues to provide a layer of protection against rekindling.

The broad application range of dry chemical extinguishers enhances their firefighting capabilities. Whether it is a small household fire or a large industrial blaze, dry chemical fire extinguishers can be used to suppress flames effectively due to their versatile application methods.

C. Suitable environments for dry chemical fire extinguishers

Dry chemical fire extinguishers are suitable for various environments, including residential settings, commercial and industrial spaces, as well as automotive and marine applications. They are commonly found in homes, offices, factories, retail stores, restaurants, and vehicles.

In residential settings, dry chemical fire extinguishers can be easily accessible in kitchens, garages, and bedrooms to protect against small fires that may occur from cooking or electrical appliances. In commercial and industrial spaces, these extinguishers are commonly installed in areas where flammable materials or processes are present, such as laboratories, chemical storage areas, or workshops.

Dry chemical fire extinguishers are also commonly seen in automotive and marine applications, where the risk of fires due to fuel or electrical systems is prevalent. Vehicle fires can be particularly hazardous, and having a dry chemical fire extinguisher readily available can help mitigate the situation until professional help arrives.

IV. Proper Handling and Maintenance of Dry Chemical Fire Extinguishers

A. Inspection and maintenance procedures

To ensure the effectiveness and reliability of dry chemical fire extinguishers, regular inspection and maintenance are essential. The following procedures should be followed:

- Regular visual inspections: Fire extinguishers should be visually inspected monthly to ensure they are in good working condition. The inspection should include checking for any signs of damage, corrosion, or leaks. The pressure gauge should also be checked to ensure it is within the recommended range.

- Recharging and hydrostatic testing: Dry chemical fire extinguishers need to be recharged after use or if there is a loss of pressure. The recharging process involves refilling the extinguisher with the appropriate dry chemical agent. Additionally, hydrostatic testing should be conducted periodically to ensure the integrity of the extinguisher’s pressure vessel. This testing involves pressurizing the extinguisher to a specified pressure and checking for any leaks or defects.

B. Proper storage and accessibility

Proper storage and accessibility of dry chemical fire extinguishers are crucial to ensure their effectiveness during emergencies. Consider the following factors when storing and placing extinguishers:

- Ideal locations for storing extinguishers: Fire extinguishers should be stored in easily accessible locations, preferably near exits or where fire hazards are present. In residential settings, it is recommended to have at least one extinguisher per floor, with additional units in areas prone to fire, such as the kitchen, garage, or workshop. In commercial and industrial spaces, extinguishers should be strategically placed in areas where fire risks are higher, such as near flammable materials or electrical equipment.

- Ensuring easy access during emergencies: Extinguishers should be mounted on brackets or placed in cabinets designed specifically for fire extinguisher storage. The cabinets should be clearly labeled and easily accessible, with unobstructed access. It is crucial to ensure that extinguishers are not blocked by furniture, equipment, or other objects that may hinder quick access during emergencies.

V. Limitations and Considerations

A. Residue and clean-up

After discharging a dry chemical fire extinguisher, a residue is left behind, which may require clean-up. It is important to understand the aftermath and follow safe procedures for residue disposal and clean-up:

- Understanding the aftermath of dry chemical discharge: The dry chemical agent used in extinguishers can leave behind a fine powder residue. This residue may be corrosive and can potentially damage sensitive equipment or electrical systems if not properly cleaned.

- Safe residue disposal and clean-up procedures: The residue should be carefully swept or vacuumed using a HEPA-filtered vacuum cleaner. It is important to avoid using air blowers or high-pressure water for clean-up, as they can spread the residue. The collected residue should be disposed of in accordance with local regulations for hazardous material disposal.

B. Potential damage to sensitive equipment

When using dry chemical fire extinguishers in areas with sensitive electrical or electronic equipment, certain considerations need to be taken into account:

- Electrical and electronic equipment considerations: The fine powder residue from dry chemical extinguishers can cause damage to electrical and electronic components. It is essential to assess the potential risks before discharging the extinguisher near sensitive equipment. If possible, power should be shut off to the equipment before using the extinguisher.

- Minimizing collateral damage during discharge: When using a dry chemical fire extinguisher near sensitive equipment, it is important to direct the discharge away from the equipment and towards the base of the fire. The sweeping method of application may be more suitable in these situations to minimize the risk of the discharge affecting the equipment.

By providing comprehensive training and education on dry chemical fire extinguishers, individuals can develop the necessary skills to respond effectively to fires and contribute to overall fire safety in their homes, workplaces, and communities.